Making Through Wire Musky Lures

Making through wire musky lures is something that not a lot of people understand. But in order to make a musky lure that will endure the vicious strikes and severe punishment it will be subjected to, it’s pretty imperative that every lure used to catch musky be fitted with through wire construction.

Making through wire musky lures is something that not a lot of people understand. But in order to make a musky lure that will endure the vicious strikes and severe punishment it will be subjected to, it’s pretty imperative that every lure used to catch musky be fitted with through wire construction.

We want to show you how making through wire musky lures can be done by even novice lure makers. We have a video below that will demonstrate this technique, step by step. Best of all, the lure maker in this video uses an oversized lure, to make it easier to see the details of what’s being done.

Why Through Wire Construction?

The objective behind through wire construction is to create lures that will last longer and stand up to extreme conditions. Musky lures are just one example. Another good example would be lures made to catch big striped bass, or even big Peacock Bass in South America.

When a lure uses through wire construction, it will be virtually impossible for a big fish to pull the hooks from the lure. It basically eliminates a point of failure by replacing screw eyes with heavy-duty twisted wire.

How Does it Work?

Through wire construction uses a solid piece of heavy wire that runs from the nose of the lure, through to the tail hook. Additionally, some lure makers run the wire from the nose to the belly. All in all, the wire aspects of the lure are pretty close to indestructible, at least by the fish.

On most baits, the wire in the nose acts as the line tie. The wire that exits the rear of the bait is the hook hanger for the rear hook. The wire is twisted to create hook attachments that will stand up to abuse. If the lure maker chooses to run a wire to the belly hook this will eliminate the need for a screw eye in the belly.

Why Not Use Screw Eyes?

Screw eyes work well under “normal” conditions. But under the extreme conditions created by large muskies, a screw eye would more than likely be yanked from the lure body after just a few fish.

Some lure makers like to use epoxy to hold their screw eyes in place. And this is a great idea, but it still won’t create an attachment point strong enough to stand up to hooking, fighting and landing several good muskies or other large gamefish.

The Actual Process of Making Through Wire Musky Lures

Now it’s time to put theory behind us and get to work with the actual process of making through wire musky lures. Because this process has a few different steps, we have included three different videos below. These three videos cover the process pretty thoroughly.

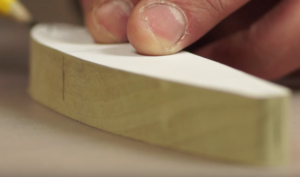

In the first video below you will be shown how to run the wire through the body of your lure.

The second video shows how to drill through the center of your wood lure body, creating a path for your wire to run through.

The third video will show you how to twist your wire to create the loops necessary to hold the hooks and tie your line to. You will also learn how to bend the wire in a way that is sure to hold the hooks in place, even under the most demanding conditions.

We’ve also included a 4th video that shows a couple other methods for wiring a wood lure.

How to drill a hole through the center of your lure.

How to Make a Tail Loop in Your Wire

Wiring a Wooden Lure

Items used for this project:

- Wire Forms & Shafts

- Bulk Wire Coils

- Round Nose Pliers

- Treble Hooks

- Wood Lure Bodies

- Lure Eyes

- Screw Eye Base Eyelet

If you enjoyed this post, please be sure to like it and share it with your friends.

And, as always, if you need any kind of lure-making supplies, be sure to visit our website, at http://lurepartsonline.com

Making a wood trout glide bait is a great way to handcraft a lure that will catch a variety of gamefish. With a glide bait you can expect to catch Largemouth and Smallmouth Bass, Northern Pike and Musky. It can also be used for other large freshwater fish around the globe.

Making a wood trout glide bait is a great way to handcraft a lure that will catch a variety of gamefish. With a glide bait you can expect to catch Largemouth and Smallmouth Bass, Northern Pike and Musky. It can also be used for other large freshwater fish around the globe. Paul starts out by showing us how he shapes his initial piece of wood. He draws out the desired shape on his wood material, using a paper template. Then he cuts it on a band saw. He then refines it a bit, using pencil marks and some sanding.

Paul starts out by showing us how he shapes his initial piece of wood. He draws out the desired shape on his wood material, using a paper template. Then he cuts it on a band saw. He then refines it a bit, using pencil marks and some sanding. Paul goes into great detail about how he creates the facial details of the trout, using more paper stencils, double-sided tape and epoxy. The results of this are impressive, as they give the face area of the lure a 3-dimensional realism.

Paul goes into great detail about how he creates the facial details of the trout, using more paper stencils, double-sided tape and epoxy. The results of this are impressive, as they give the face area of the lure a 3-dimensional realism.

Building a rattle chamber in a wooden fishing lure is the best way to overcome the lack of sound in most wooden fishing lures.

Building a rattle chamber in a wooden fishing lure is the best way to overcome the lack of sound in most wooden fishing lures. Zara Spooks and other walking topwater lures have been around for decades. They have have accounted for some giant bass over the years. There’s something about that cigar-shaped body zig-zagging back and forth across the surface of the water that big bass and other gamefish just can’t pass up.

Zara Spooks and other walking topwater lures have been around for decades. They have have accounted for some giant bass over the years. There’s something about that cigar-shaped body zig-zagging back and forth across the surface of the water that big bass and other gamefish just can’t pass up.

Want to learn how to make a topwater bass popper? We have a great tutorial video for you right here.

Want to learn how to make a topwater bass popper? We have a great tutorial video for you right here. Stand the piece upright and place a nickel on the top end, offset so that the nickel touches one side of the circumference, but not the other.

Stand the piece upright and place a nickel on the top end, offset so that the nickel touches one side of the circumference, but not the other. Now we’ll start the actual carving, using a utility knife, or something similar.

Now we’ll start the actual carving, using a utility knife, or something similar.